Project DetailsCheyney UniversityLocation - Cheyney, PAProject Scope Installed new water main Completed sewer and stormwater drainage systems Constructed new curb and sidewalk

When most people think about sustainability in construction, their minds jump to renewable materials, energy-efficient equipment, or green certifications. But there’s a quieter, equally powerful contributor to a sustainable future: asphalt maintenance programs.

At Delaware Valley Paving, we believe that maintaining what you already have is one of the most impactful — and often overlooked — ways to reduce environmental impact. Here’s why.

Every year that a parking lot, roadway, or pathway remains in good condition is a year that avoids the energy, materials, and emissions needed for full replacement. Preventative maintenance like sealcoating, crack sealing, and patching slows deterioration, extending pavement life by years — sometimes decades.

By reducing the frequency of major reconstruction, we minimize waste sent to landfills and conserve the natural resources used to produce new asphalt.

Full-depth asphalt replacement involves heavy hauling, high heat, and intensive equipment — all of which contribute to greenhouse gas emissions. In contrast, targeted maintenance uses fewer materials, requires less fuel, and has a much smaller carbon footprint.

Even small, routine actions like filling cracks before water seeps in can prevent large-scale repairs that would have a significantly higher environmental impact.

A well-maintained asphalt surface prevents water infiltration into the subbase, protecting not only the pavement but also the surrounding drainage systems. This helps keep stormwater infrastructure functioning as designed, reduces erosion, and supports compliance with environmental regulations.

Asphalt production relies on aggregates and binders that come from finite natural resources. Extending the life of existing pavement through proactive care means less demand for new raw materials — a direct win for conservation efforts.

Sustainability isn’t just about the planet — it’s about long-term cost efficiency. Preventative maintenance can cost a fraction of full reconstruction, allowing property owners to protect budgets while also protecting the environment.

At Delaware Valley Paving, our maintenance programs are built to maximize pavement life, reduce environmental impact, and keep your property looking its best year after year. From proactive inspections to customized repair plans, we help clients take a long-term, sustainable approach to pavement care.

Because the greenest pavement is the one you don’t have to replace.

Ready to make your pavement part of your sustainability plan?

Let’s talk about a customized asphalt maintenance program for your property.

Project DetailsCheyney UniversityLocation - Cheyney, PAProject Scope Installed new water main Completed sewer and stormwater drainage systems Constructed new curb and sidewalk

Arizona, Asphalt Paving, Drivelanes, Line-Striping

ProjectAmazon Distribution Center - Phoenix, ArizonaProject Gallery[el_masonry_gallery image_ids="281445,281446,281447,281448,281449,281450,281451,281452,281453" number_of_columns="2" image_size="full" disable_lazy_loading="off" enable_lightbox="on"...

ADA Compliance, Asphalt Paving, Delaware

ProjectLowe's Store - Lewes, DelawareProject Gallery[el_masonry_gallery image_ids="281435,281434,281433,281432,281429,281428" number_of_columns="2" image_size="full" disable_lazy_loading="off" enable_lightbox="on" _builder_version="4.27.0" _module_preset="default"...

ADA Compliance, Asphalt Paving, Connecticut

ProjectLowe's Store - New Haven, CTProject Gallery[el_masonry_gallery image_ids="281424,281425,281426,281427,281428,281429" number_of_columns="2" image_size="full" disable_lazy_loading="off" enable_lightbox="on" _builder_version="4.27.0" _module_preset="default"...

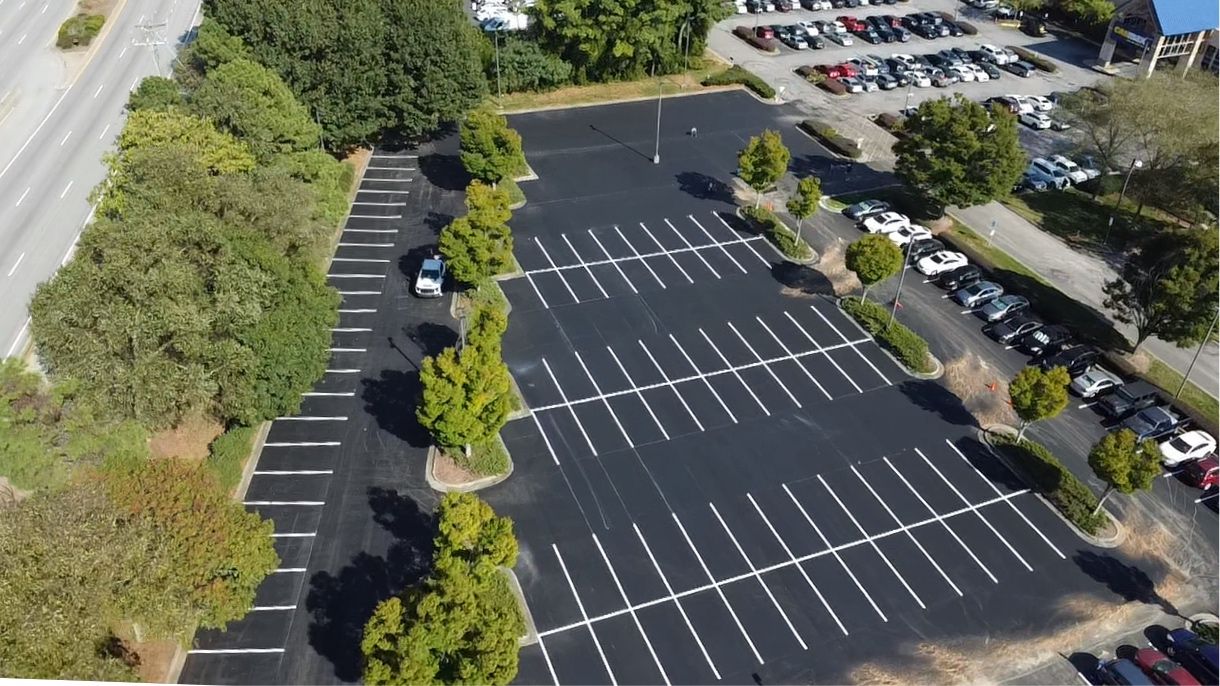

📍Greensboro, NC

Project Scope: This project included asphalt milling and paving, followed by parking lot line striping to restore layout and flow. All work was completed in accordance with ADA compliance standards and supported by Construction Materials Testing (CMT) to ensure quality and performance.

📍Boone, NC

Project Scope: This project included crackfilling, sealcoating, and fresh line striping to restore and protect the asphalt surface. All work was completed in compliance with ADA requirements.

📍Orlando, FL

Project Scope: This 10-acre project included well point de-watering, excavation, and installation of 1,500 LF of 36″ RCP across 8 inlet structures. Our team constructed two retention ponds, completed fencing, concrete, and ADA upgrades, and handled full landscaping, irrigation, and lighting—delivering a fully integrated site solution from the ground up.

📍Sandy, UT

Project Scope: The scope of work included traffic control and barricading for safety, asphalt removal and milling, and full asphalt replacement. We also completed line striping, installed signage, and ensured all work met ADA compliance standards.

📍Everett, MA

Project Scope: This project involved removing and replacing concrete sidewalk, installing an ADA-compliant curb ramp, and forming and pouring a new concrete compactor pad. We also completed vertical and horizontal joint repairs, asphalt restoration, and line striping touch-ups to finish the site.

📍Abington, MA

Project Scope: This project included single-course paving replacement and binder repair in areas of failed asphalt. We removed existing pavement, regraded for proper ADA slope, and repaved the surface. Additional work included removing and replacing concrete sidewalks and curbs, sealing joints and cracks in concrete, refreshing line striping, repainting existing bollards, and installing new ADA sign posts and bollards.

📍Norwood, MA

Project Scope: This project involved interior concrete repairs and full concrete replacement in select areas to restore surface integrity and ensure long-term durability.

📍Norcross, GA

Project Scope – 595,000 sq. ft. project, 2-inch mill and pave for the sales lot and a 4-inch mill and pave for the customer lot

📍Savannah, GA

Project Scope – 81,000 SQFT R&R Concrete Project: Removed 12″ of saturated soil and replaced subgrade, Installed 6″ perforated drainpipes draining to a retention pond, Reinforced subgrade with geogrid and 12″ of compacted stone

📍Kennesaw, GA

Project Scope – Removed and disposed of existing sidewalk, Topdressed existing stone as required, Formed and poured new 4″ 4000 PSI Class A concrete with a broom finish

📍Stone Mountain, GA

Project Scope – Light-duty paving, concrete curbs, and heavy-duty concrete installed, Relocated and installed new light poles to improve visibility, Demolished concrete islands and installed ADA-compliant ramps to improve accessibility, Bollards added to protect pedestrian walkways and building perimeters, Reflective, water-based line striping applied

📍Locust Grove, GA

Project Scope – 6″ Mill and Pave using fibers for sustainability, Line striped entire lot

📍McDonough, GA

Project Scope – 5″ Mill and Pave using fibers for sustainability, Line striped where needed

📍Snellville, GA

Project Scope –This project included mill and pave operations, sealcoating, and crackfilling to restore and protect the asphalt surface. We also replaced curbs, installed new bollards and signage, repaired utility covers, and made ADA upgrades — all completed with proper traffic control for a smooth and safe execution.

📍Cheyney, PA

Project Scope: Installed new water main, completed sewer and stormwater drainage systems, and constructed new curb and sidewalk

📍Huntingdon Valley, PA

Project Scope: 2″ mill and pave over 7,994 Sq Yd, Installed 6.5′ x 6″ concrete-filled steel pipe bollard, Excavated trench up to 18″ deep, backfilled with stone and asphalt, and installed 4″ asphalt with hot tar edges

📍Phoenixville, PA

Project Scope: 2″ Mill & Pave of Community Roadways and Parking Lot, Drain Inlet Replacements throughout community, ADA Repairs, Line Striping

📍Philadelphia, PA

Project Scope: 2″ overlay on milled surface, Sidewalk replacement (5″), Curb installation (6″ standard & 4″ surmountable), ADA ramps (Type 1A), Decorative concrete bollards

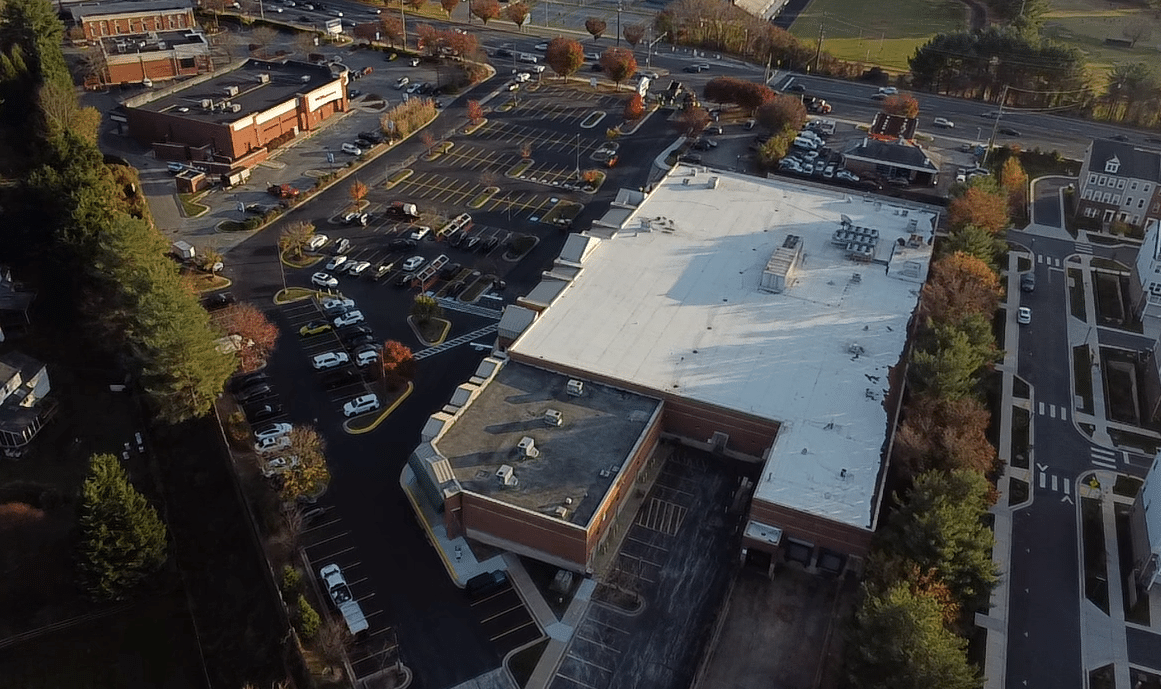

📍Lancaster, PA

Project Scope: 2″ Mill and Pave, Installed new wheel stops, Line striped the entire lot and road

📍Pottsville, PA

Project Scope: Excavated 9.5″ concrete + 6″ stone, Installed geogrid + 6″ crushed aggregate, Used concrete fiber reinforcement and concrete caulking, Heavy Duty Paving which included removing a 14″ section, installing geogrid, adding 7″ stone base + 5″ asphalt binder

📍Harrisburg, PA

Project Scope: 2″ Pave, Applied acrylic resurfacer followed by multiple color coats, Line Striped court, Installed concrete curbs

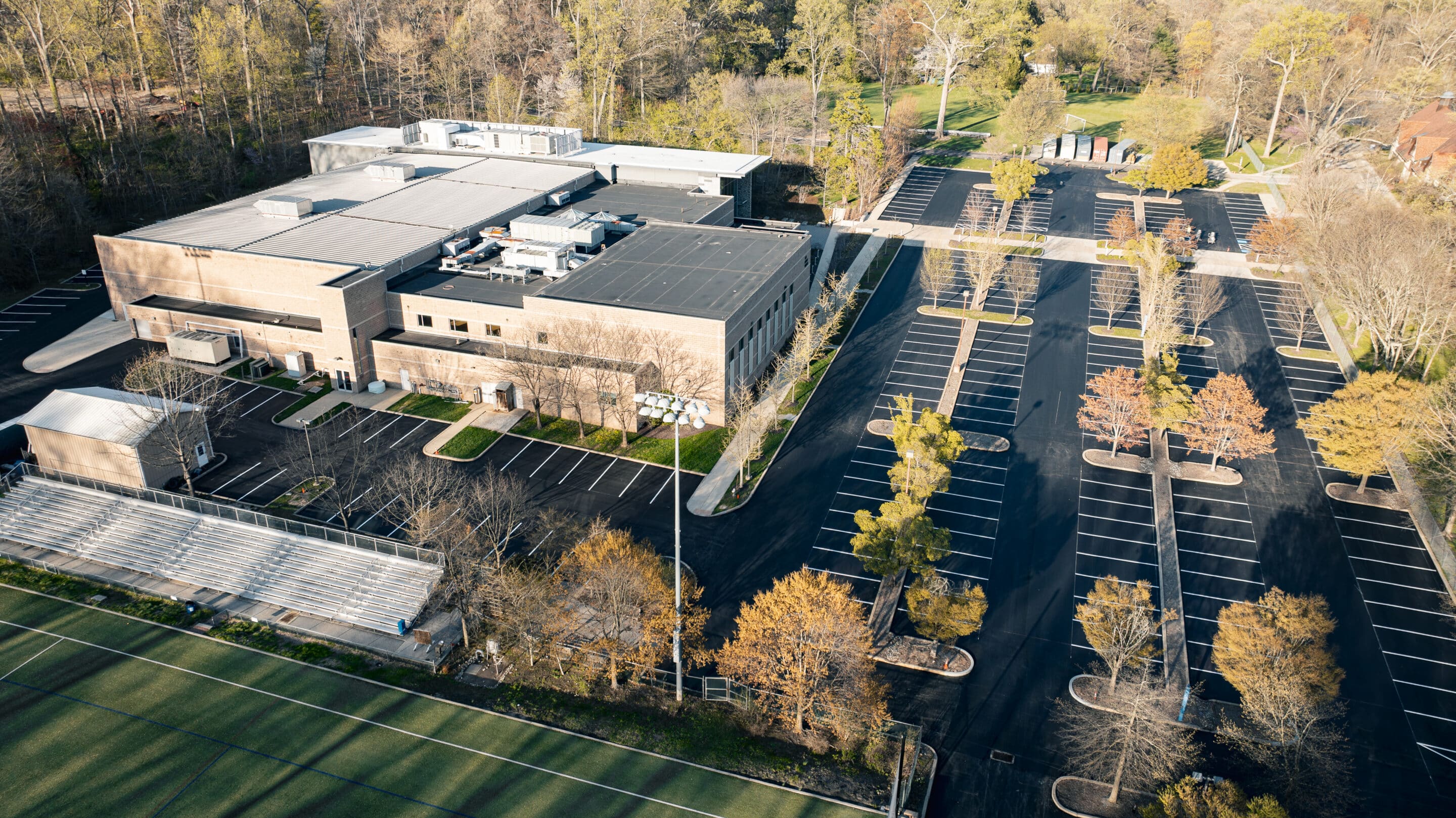

📍Radnor, PA

Project Scope: 2″ Mill and pave over 32,350 SY, Crackfilled 3,235 LF, Line striped entire lot and trail, 75 LF of curb replacement

📍Denver, CO

Project Scope – 4 in. Mill and Pave, Crack filling, Line Striped entire lot, Site Improvements

📍Newark, NJ

Project Scope – Full-depth asphalt removal and heavy-duty concrete replacement, including 10″ reinforced concrete pads and upgraded drainage swales. Completed with fresh line striping

📍Middletown, DE

Project Scope – 2.5″ mill and pave over 78,923 sq. yds., Removed and replaced 77 speed bumps, Removed and reinstalled existing wheel stops with rear pins, Line striped entire lot

📍Lewes, DE

Project Scope – Asphalt Resurface, Removed and replaced curb, ADA bollard cover and sign, line striped entire lot

📍Newark, NJ

Project Scope – 4″ Mill and Pave, 8″ heavy duty concrete replacement, Line striped entire facility and 24 new numbers at the bay doors

📍New Brunswick, NJ

Project Scope – Installed 3″ of binder and paved 2″, 8″ of concrete paving, installed a 4″ concrete sidewalk and curb, installed 8″ dumpster pads, Installed STOP signs and new bollards, Line striped entire lot

📍Morrisville, NJ

Project Scope:

📍Robbinsville, NJ

Project Scope – Concrete Demolition

📍West Windsor, NJ

Project Scope – Seal coated (2 layers) entire lot, Crack filled where necessary, Line striped

📍NJ

Project Scope – Performed 1.5″ Mill and Pave, Line stripped entire lot

📍Baltimore, MD

Project Scope – Demolition & Site Preparation, Installed 15″ and 18″ reinforced concrete pipe (RCP), Temporarily removed and reinstalled chain link fence, Performed 2″ mill and pave of designated asphalt areas, Applied fresh line striping across the entire lot, Poured new concrete surfaces and installed new curbing, Supplied and installed new wheel stops throughout parking areas

📍Gaithersburg, MD

Project Scope – 4″ Mill and Pave, ADA Compliance, Installed new bollards and signage, Removed and replaced concrete sidewalk, curb, and gutter, Line striped entire lot

📍Glen Burnie, MD

Project Scope – Two-Course Paving Repairs, 5″ Mill and Pave to areas needed, Applied two coats of sealer, Line striped entire lot

Lowe’s Store (Jackson) – 1.5″ Mill and Pave, Line Striped entire lot, CMT Testing

Governor’s Square Mall (Clarksville) – Mill & Paved 5 different areas at different specs., Full depth patching, Seal coated over 124,664 SY, Crack filled 12,000 LF, Line striped entire lot

Walmart (Cobblestone) – Pavement replacement that included 16” of pavement, 12” of new stone base, and a 3” binder topped with a 2” fiber-reinforced surface course. Replaced concrete and line stripped the entire lot

Lowes (Glenmont) – Resurfaced Existing Asphalt, Removed & Replaced Concrete Sidewalk, Line Striped entire lot, ADA Compliance

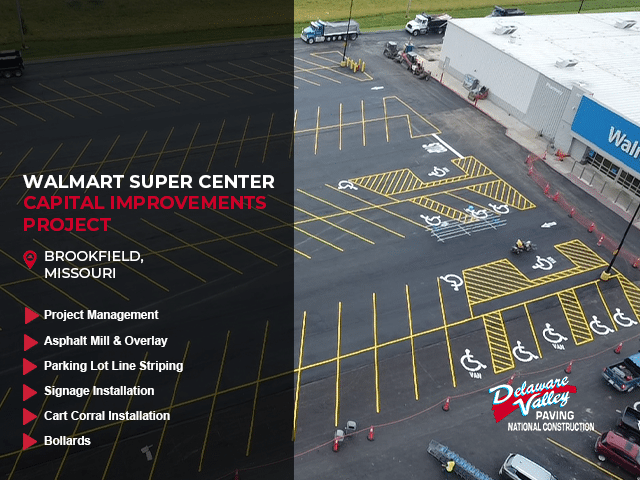

Capital Asphalt Replacement